One String to Pull Them All: Fast Assembly of Curved Structures from Flat Auxetic Linkages

Abstract

We present a computational approach for designing freeform structures that can be rapidly assembled from initially flat configurations by a single string pull. The target structures are decomposed into rigid spatially varied quad tiles that are optimized to approximate the user-provided surface, forming a flat mechanical linkage. Our algorithm then uses a two-step method to find a physically realizable string path that controls only a subset of tiles to smoothly actuate the structure from flat to assembled configuration. We initially compute the minimal subset of tiles that are required to be controlled with the string considering the geometry of the structure and interaction among the tiles. We then find a valid string path through these tiles that minimizes friction, which will assemble the flat linkage into the target 3D structure upon tightening a single string. The resulting designs can be easily manufactured with computational fabrication techniques such as 3D printing, CNC milling, molding, etc. in flat configuration that, in addition to manufacturing, facilitates storage and transportation. We validate our approach by developing a series of physical prototypes and showcasing various application case studies, ranging from medical devices, space shelters, to architectural designs.

Actuation Demos

A small scale chair deployment

A small scale Lilium deployment

Human-scale chair deployment and disassembly into a flat, compact configuration

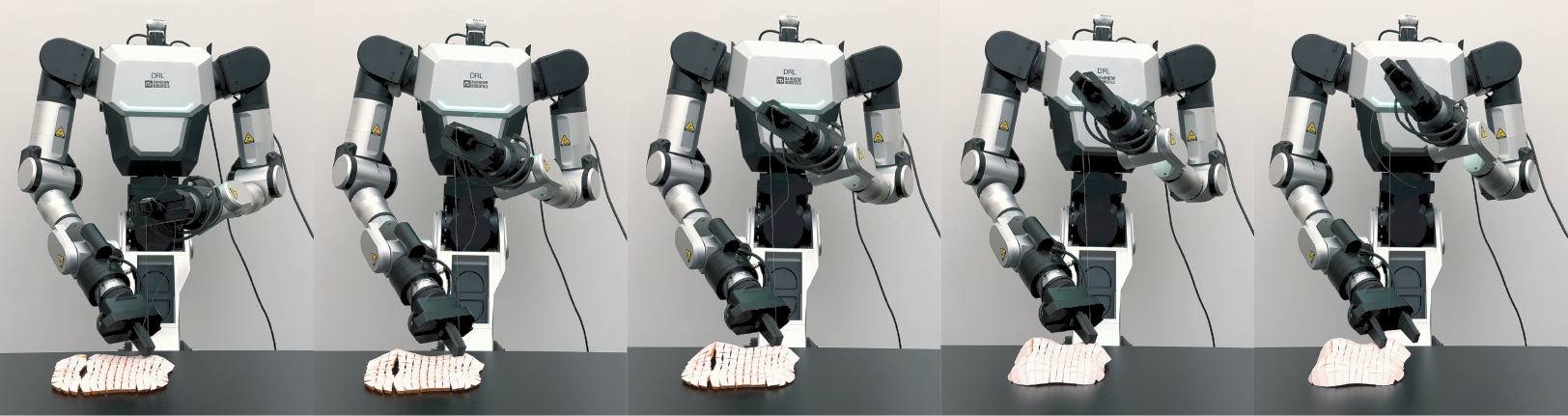

A Humanoid robot deploying Lilium structure with a single string pull

Diverse Doubly Curved Surfaces

Five Simulated structures were transformed from flat configurations (bottom) made of interconnected tiles (top) with a single pull of a string. The middle row shows, in red, the optimized string path and lift points for each object.

Deployment Simulation

We implement a rigid-body physics simulation that models contact and string-driven actuation to evaluate a physically valid deployment.

Fabricated Prototypes

Four Facricated structures, which are manufactured via multi material 3D printing (FDM), using orange PLA for the rigid tiles and white TPU for the hinges.

Applications

Personalized medical items such as splints (Left) and posture correctors (Right). Both are optimized for a given patient, then manufactured, stored and carried flat, and can be easily assembled by a single string pull.

Consumer goods such as furniture. We designed and built a functional human-scale chair: assembled configuration (top-left) and flat configuration views (top-right). Timelapse demonstrates reversible deployment.

Modular space habitat. Flat-manufactured modules enable compact transport and rapid robotic deployment in hostile extraterrestrial environments.

Rapid assembly of architectural structures. Frames are manufactured off-site, transported flat, and deployed onsite using minimal lifting infrastructure.

Simplified autonomous robotic assembly. A single string-pull actuation is significantly easier to plan than assembling individual modules.

BibTeX

@article{OneStringtoPullThemAll,

author = {Akib Zaman and Jacqueline Aslarus and Jiaji Li and Stefanie Mueller and Mina Konakovi{\'c} Lukovi{\'c}},

title = {One String to Pull Them All: Fast Assembly of Curved Structures from Flat Auxetic Linkages},

journal = {ACM Transactions on Graphics},

volume = {44},

number = {6},

articleno = {234},

numpages = {18},

month = dec,

year = {2025},

publisher = {Association for Computing Machinery},

address = {New York, NY, USA},

doi = {10.1145/3763357},

url = {https://doi.org/10.1145/3763357},

keywords = {computational fabrication, string-based actuation, metamaterials, inverse design, deployable structures}

}